Handmade Knives

About the maker

Roger Harrington has been a professional knife maker since 1997 trading as Bison Bushcraft or in his name, although that isn't where his passion for making knives started. As a youth in the 1970s, any bit of metal he came by was fashioned into something sharp and this culminated with him getting into trouble at school for making a pretty good replica of a commando knife ( although he still went on to win the school prize for metalwork). This was his earliest influence in the knife world seeing the beauty of The Fairbarn Sykes knives illustrated on the back of the War picture library magazines. His adult work career has involved various engineering and bushcraft related jobs giving him the ideal skill set to design and make practical, comfortable and functional outdoor tools. Roger has to date made knives for bush crafters, the military, hunters, fishermen and a whole host of other international customers who have a use for a high quality practical outdoor tool. Roger has designed and made knives for other organisations as well as licensed his designs to factories who produce knives in bulk. He is always open to new designs and materials and looks forward to new challenges in customers designs that he can produce in his well equipped Sussex workshop.

Handle materials

Woods

The woods I use are chosen to highlight the beauty of nature. I choose natural colours and grain structures that are highlighted in the small area that is a knife handle. I use both stabilised wood that is vacuum impregnated with methacrylate resin (I do this operation myself) or open pored wood that I treat with gun stock oil. Both give a hard wearing natural finish with the stabilised wood needing no maintenance and the open pored needing an occasional oiling and polishing to maintain it's good looks and stability.Antler and horn

Antler for knife scales is becoming harder to find these days, I do have a small stock and am always on the lookout for suitable pieces. It is without a doubt very good looking and gets better looking as it gets older. Along with Buffalo horn I tend to use it mainly for bolsters these days. Be aware that not all antler is suitable for the task as it needs to be thick walled and comes mainly from foreign species of deer. So I couldn't use the antler from UK species.Micarta (Tufnol) and G10

These materials are hard wearing and waterproof materials utilising layers of material such as paper, linen, canvas or fibre glass encapsulated in a coloured thermosetting resin. Although they don't have the individuality or unique appeal of natural materials, they have their place in the need for low maintenance handles. It is possible to get some good effects when shaping handles across the filler layers.Fibre liners

A gasket layer employed between the blade steel and the handle scales. Although it acts just as a gasket should soaking up any movement in the steel and handle due to environmental and humidity changes it is more often employed just for it's looks giving a definitive outline to natural beauty.Blade steels

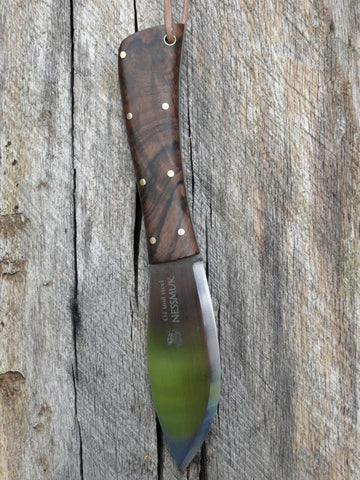

O1 Tool steel

Often refered to as guage plate or ground flat stock (GFS) this is the closest you can get to traditional high carbon tool steel. The 1% carbon gives it excellent edge holding capabilities and it is easy to sharpen. It is in no way stainless and should be cleaned after use and kept oiled. However over time it builds up a dark grey patina that adds to it's corrosion resistance. Normally hardened to 59hrc.RWL34

A stainless tool steel developed at the DAMASTEEL AB firm in Sweden. It is a powder metallurgy version of ATS-34 that was the steel championed by one of the grandfathers of modern custom knife making Bob W Loveless (Hence RWL). It's performance is exemplary, especially in the 27 degree scandi grind that I employ. It is very tough and will hold an edge for a long time. Normally hardened to 62hrc for best performance.Damasteel

Another excellent product from DAMASTEEL AB.Using modern technology to acheive the patterned damascus blade steel using the same solid state welding procedure called “Hot Isostatic Pressing” but using layers of RWL-34 with alternate layers of PMC-27 (a powder metallurgy version of 12c27) that produces a billet which can be manipulated to produce various patterns. Unlike black-smithed Damascus that can be prone to flaws,quality can be guaranteed. Damasteel is expensive and time consuming to work with several stages required to achieve those stunning looks of the end product. But worth it not only for its looks but truly outstanding performance.

The following are examples of what I generally make and I can make to your designs also. There are some ready to go out stock knives here,

https://bisonbushcraft.co.uk/collections/available-knives

or if what you’d like isn’t there Email me at info@bisonbushcraft.co.uk with any enquires.